Load Leveling Solutions: The Benefits of Flatbed Cargo Securement Equipment Accessories

In the world of transportation and logistics, the safe and

Share

Safely securing and transporting cargo is a top priority for flatbed trucking companies. Damage to cargo in transit can result in lost revenues and dissatisfied customers who have received items not up to the client’s expectations. This guide will provide an overview of the various types of Load and Cargo Securement devices available and their benefits, as well as tips and advice on how best to choose and use them.

Load securement devices can be broken down into two main categories: static components, which keep loads stationary while they are being transported, and dynamic components, which protect loads from moving on the trailer deck. Static components consist of chain binders, lever binders, ratcheting binders, winch straps, ratchet straps, and other heavy-duty tie-downs. Dynamic components are typically made from rubber, wood, aluminum, or steel and include dunnage blocks, 4×4 beveled dunnage lumber, heavy-duty dunnage board holders, coil rack, pipe stakes, and rubber non-slip friction mats for flatbed trailers.

Load securement devices are designed to create tension between two anchor points per DOT standards. When correctly used, these devices offer a downward force on cargo during transport. However, every operator is different and nobody knows how tight they are getting their transport chain. Load securement devices can cause cargo securement failures and damaged cargo if over-tightened, or under-tightened. Furthermore, it is important that every chain and strap is inspected before and after each use. During transit, “cargo securement inspections are required within the first 50 miles after loading, and then after every 3 hours, 150 miles or at duty change, whichever comes first.”

Dynamic components hold or contain cargo within specific locations on the trailer deck, create friction to prevent cargo from slippage, and support cargo securement devices during transit. These items are necessary to prevent loads from rolling or sliding off a flatbed trailer during load securement and can prevent equipment failures as a result of hard stops.

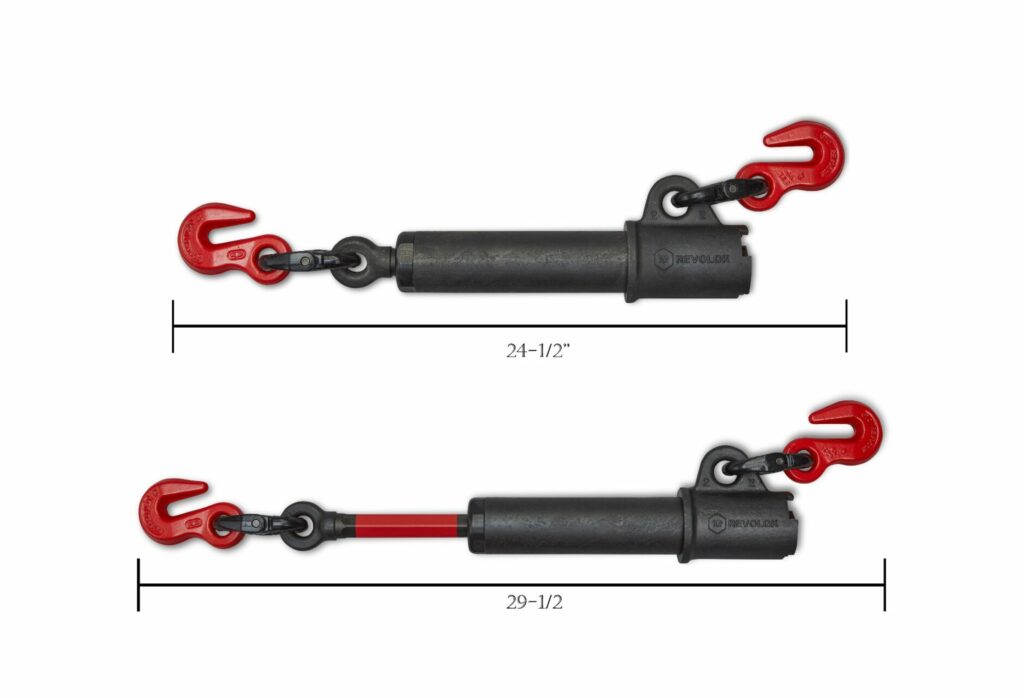

The all-new REVOLOK 6600 drill powered binder is the best professional load securement device for securing ⅜ G70 chain. This revolutionary cargo securement is faster, easier, safer, and more efficient than current chain binders. With the REVOLOK 6600, securing cargo is as simple as squeezing a button on a battery drill. No more messing around with inexact ratchet binders – just fast, easy, secure chains every time. The REVOLOK 6600 has a built-in clutch that prevents ⅜ chain from being over-tightened or under-tightened. Each time you press the trigger and hear the clutch engage you will know that your cargo is secure. Plus, this device is sourced and manufactured in the USA and built to withstand the rigors and extreme environment of the flatbed trucking industry. The REVOLOK 6600 is here to make your life easier and your cargo safer on the road.

In conclusion, understanding what each type of Load and Cargo Securement device does best will help you become more efficient and safer. Additionally, investing in quality solutions from reputable suppliers ensures peace of mind when transporting valuable cargo and volatile loads. Today’s new and exciting cargo securement technology will help shape and innovate the future of the flatbed trucking industry.

In the world of transportation and logistics, the safe and

Welcome to REVOLOK™, your trusted partner in cargo securement solutions.

Cargo securement is critical to the transportation industry, ensuring that

When it comes to securing cargo on flatbed trailers, choosing

Cargo transportation is a crucial aspect of the economy, with

As industries and businesses around the world continue to evolve

"*" indicates required fields